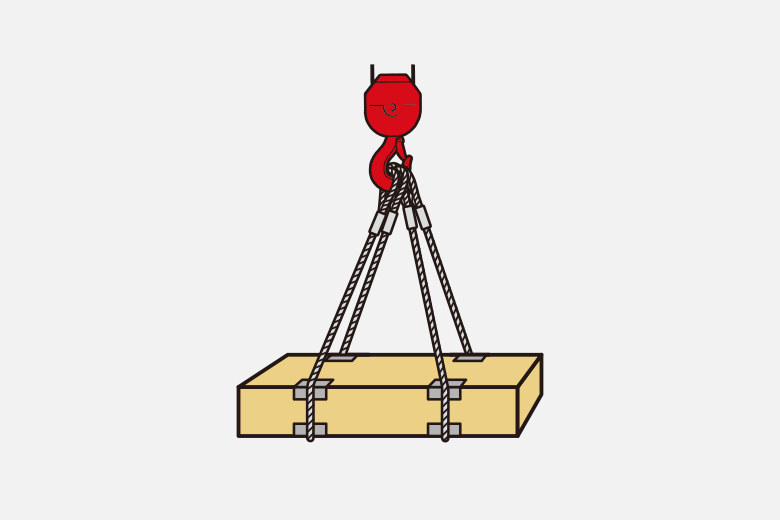

1. Measuring mass

If the mass of a load is unknown, calculate a rough estimate by visually checking the material and dimensions of the load.

As this method is prone to have a margin of error, it is important to overestimate mass.

Examples of calculating a rough estimate are as follows.

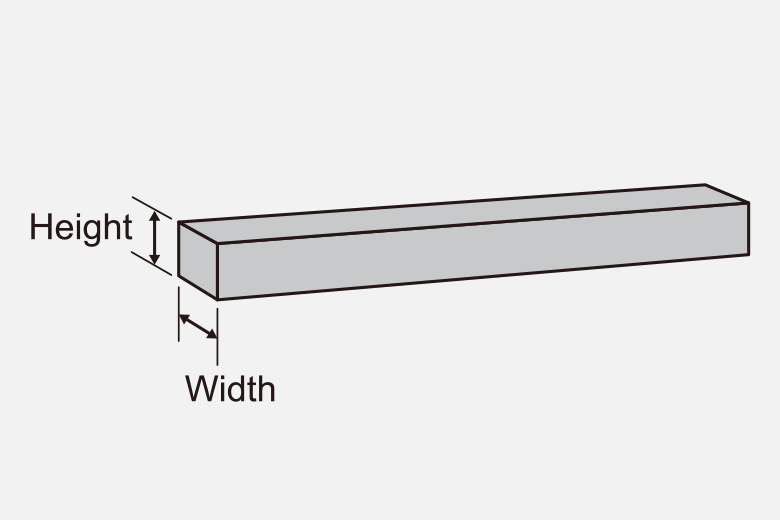

Square steel (one meter long)

Mass (in kg) → Width (in cm) × Height (in cm) × Length (in cm) × 7.85 (g/cm3)

(7.85 is the density of the steel. You can find density of the material online.)

(Example)

Width 10 cm × Height 10 cm × Length 100 cm × 7.85 g/cm3 = 78,500 g

= 78.5 kg

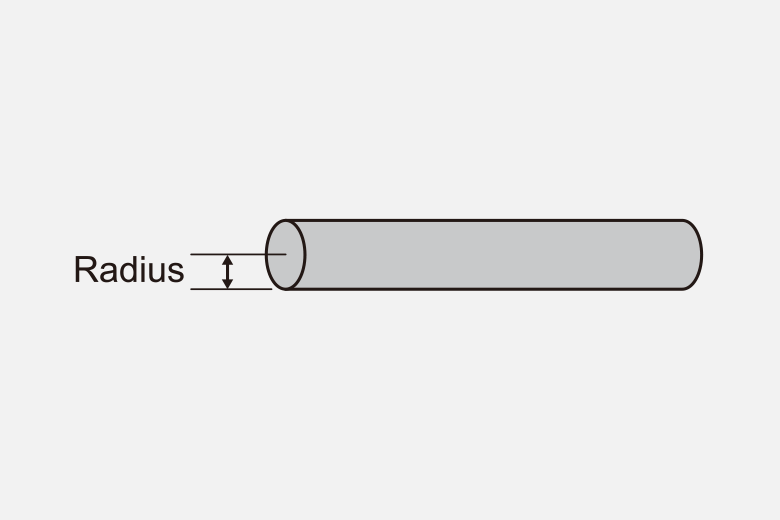

Round steel (one meter long)

Mass (in kg) → Radius (in cm) × Radius (in cm) × 3.14 × Length (in cm) ×7.85 (g/cm3)

(3.14 is the circular constant.)

(Example)

Radius 5 cm × Radius 5 cm × 3.14 × Length 100 cm ×7.85 g/cm3 = 61,622 g

= 61.6 kg

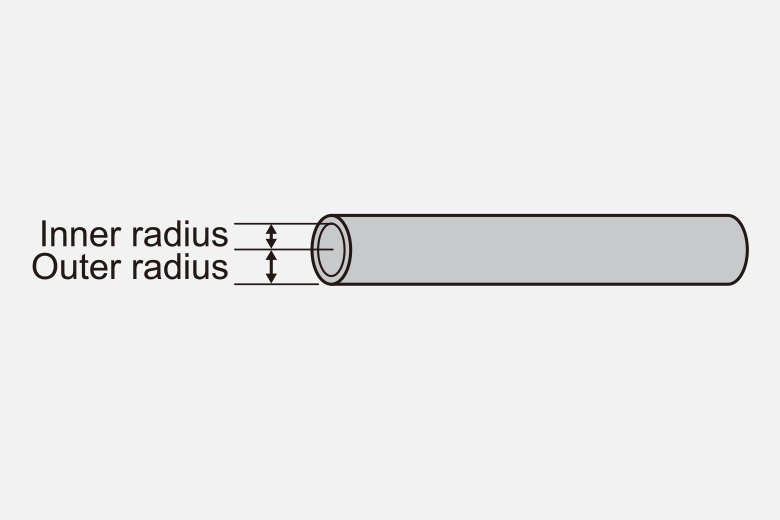

Steel pipe (one meter long)

Mass (in kg) → {Outer radius (in cm) × Outer radius (in cm) − Inner radius (in cm) × Inner radius (in cm) } × 3.14 × Length (in cm) × 7.85 (g/cm3)

(Example)

(Outer radius 5 cm × Outer radius 5 cm − Inner radius 3 cm × Inner radius 3 cm ) × 3.14 × Length 100 cm × 7.85 g/cm3 = 39,438 g

= 39.4 kg

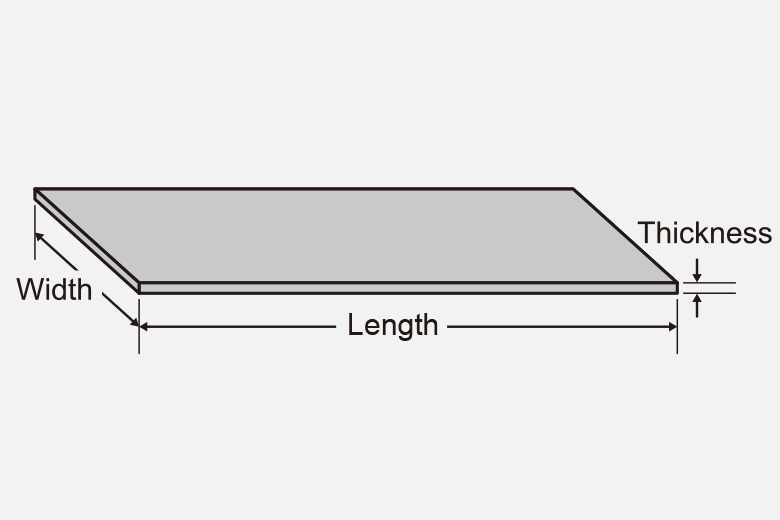

Steel plate

Mass (in kg) → Width (in cm) × Length (in cm) × thickness (in cm) × 7.85 (g/cm3)

Width 100 cm × Length 100cm × thickness 1 cm × 7.85 g/cm3 = 78,500 g

= 78.5 kg