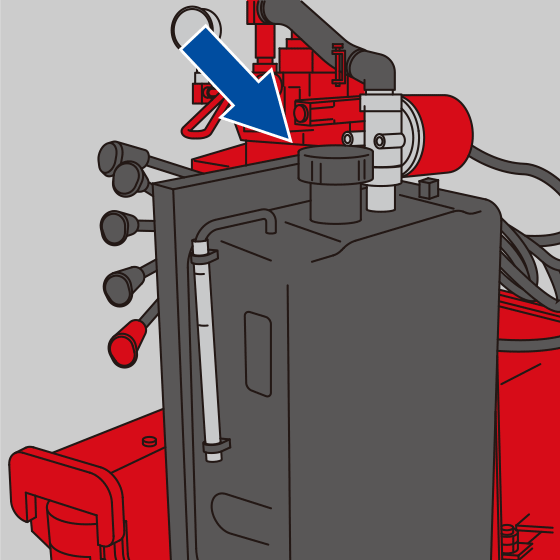

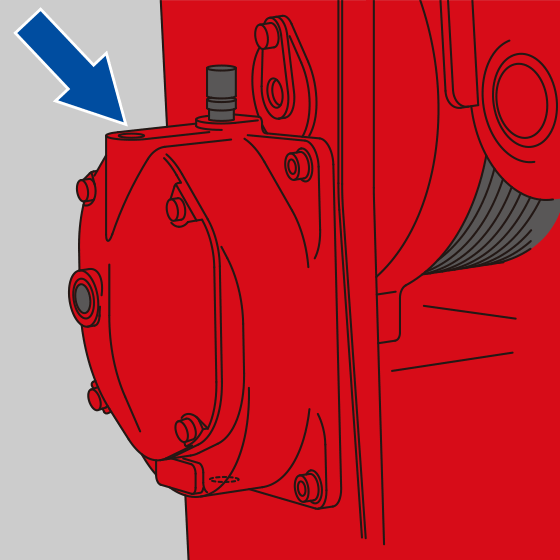

Greasing

A lack of lubrication may lead to abnormal noise or cause structural damage to components.

Proper greasing results in less friction between sliding parts and leads to them lasting longer.

Be sure to grease parts appropriately.

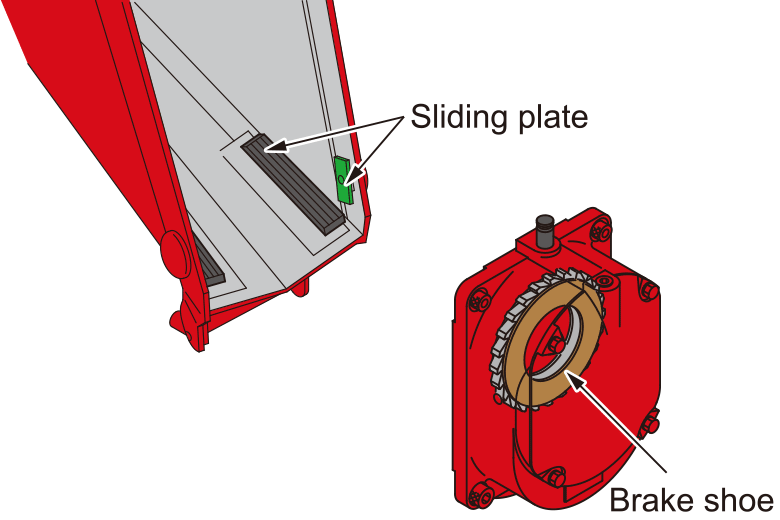

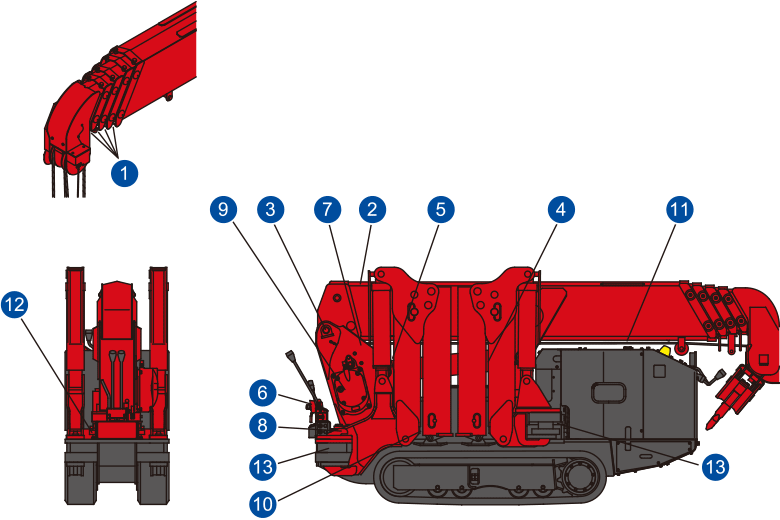

- (2) Boom sliding plates

- Boom foot pin

- (5) Derrick cylinder support pin

- Control lever

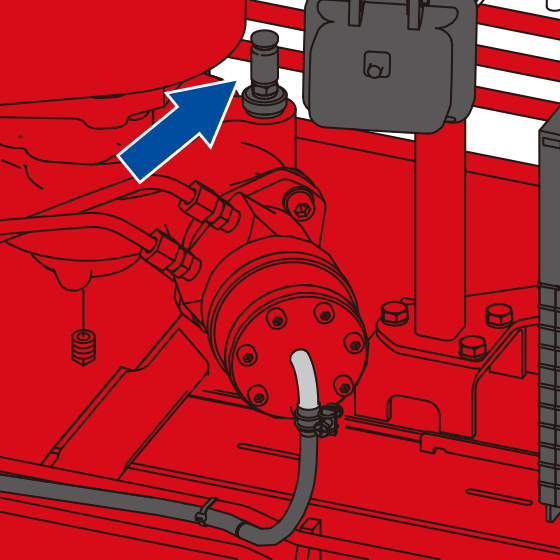

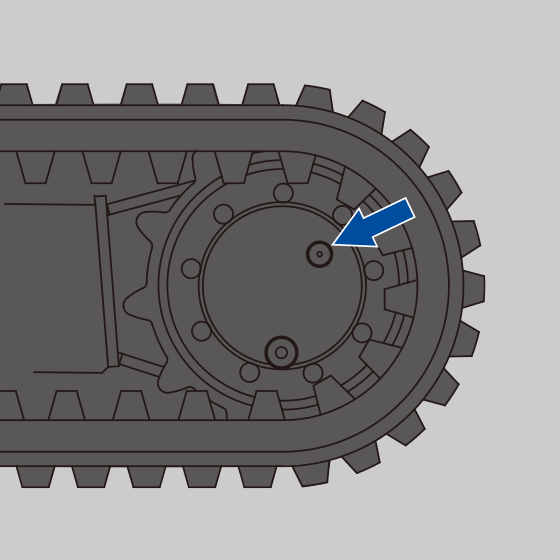

- Winch drum gear

- Slewing gear

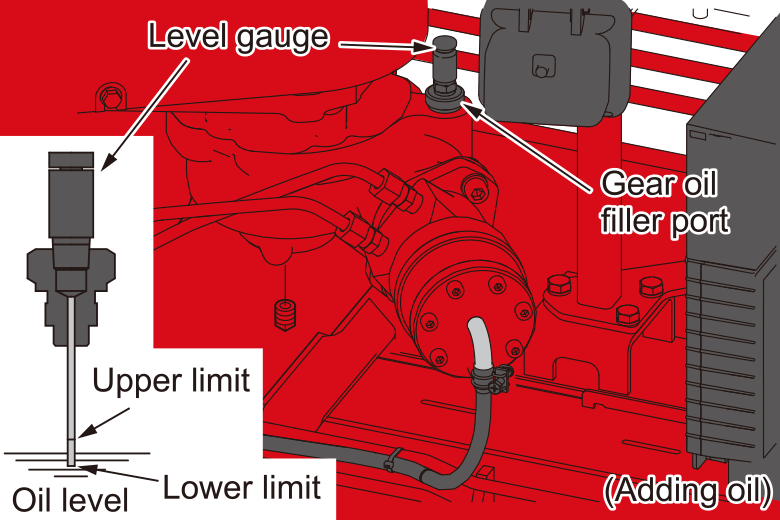

- Winch reduction gears

- Slewing reduction gears

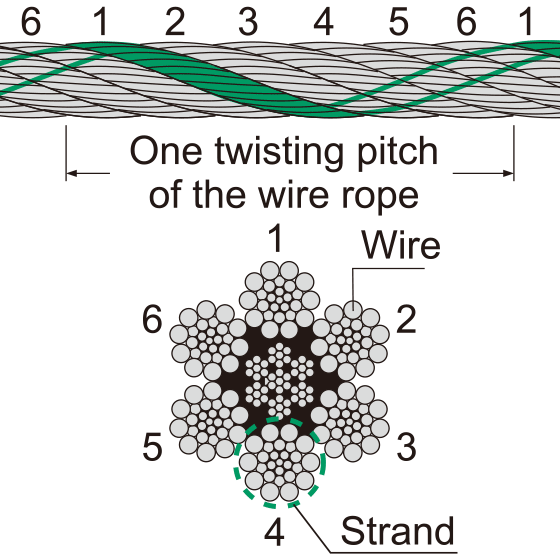

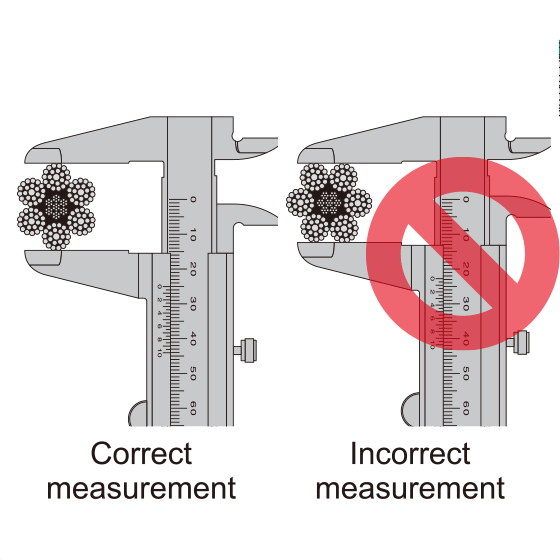

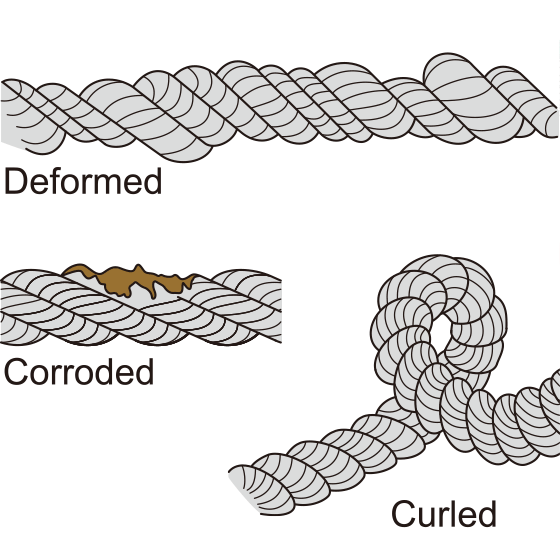

- Wire rope

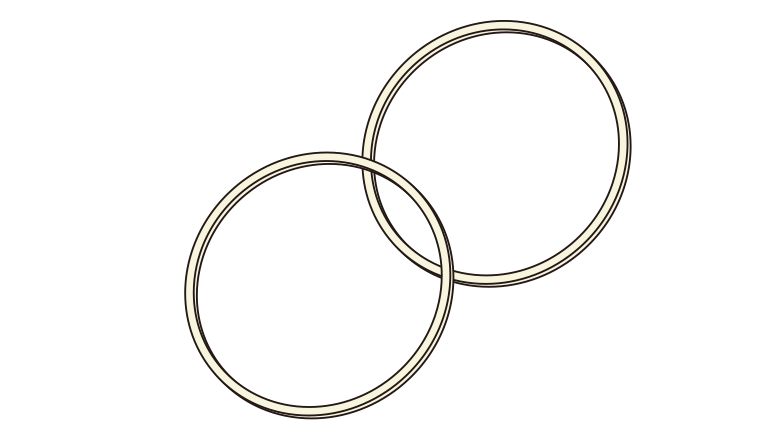

- Slewing bearings

- Outrigger fulcrum pin